One of the biggest wastes in a phosphating application is the productivity loss due to rejects & reworks. As with most multi-step chemical processes, having a clean contaminate-free surface is key to achieving a proper phosphate coating. This enables the reaction to proceed across the entire working surface area and ensures that the substrate is activated and free of problematic soils.

Organic...

Read More

In the process of aluminum cleaning, managing zincate drag-in and avoiding blistering issues is important for ensuring quality. A customer case study reveals a solution that balances quality maintenance and cost-effectiveness, highlighting the importance of improving treatment processes.

When a manufacturing customer consistently faced blistering concerns around the third metal turnover (MTO). The...

Read More

Even though they didn’t get the order, Hubbard-Hall’s cleaning team used its process knowledge expertise to solve a $1M issue for a defense manufacturer

Stewart Holloway didn’t get the sale he was looking for when he walked out of the prospective customer’s plant, but that didn’t matter to him.

“We helped them solve a potential quality issue they were facing, and that is all that matte...

Read More

Identify the Root Cause

One of the biggest challenges operators face is knowing whether a part is clean enough . Many issues can be traced back to inadequate cleaning and pretreatment of parts. Variables are changing upstream that are out of your control, which causes downstream issues. While problems can sometimes arise due to bath issues, a significant portion correlates with ineffective pretrea...

Read More

To the uninitiated, the daily operation of a phosphate bath can appear daunting – perhaps even a bit convoluted. While temperature and concentration are common parameters for most chemical applications, both phosphate baths have added complexity acid points, acid ratios, dissolved iron, sludging, heating source, & more. In this post, we will highlight some of the key features of these proce...

Read More

Manganese and zinc phosphate coatings have been utilized as established solutions for over a century, delivering proven benefits in a number of applications. Beyond their mechanical benefits and anti-corrosion properties, these coatings create an optimal surface for paint adhesion by increasing the substrate’s total surface area with the crystalline coating that is formed. However, for applicati...

Read More

One of the more frustrating aspects of being a paint applicator is having to deal with the buildup of paint on your racks and fixtures. These custom components are a considerable investment for many applicators and ensuring that they remain functional and lasting is critical to managing a process’s operation cost. Several different methods are used to maintain these components including burn-off...

Read More

Question:

Can I “overwhelm” my wastewater system?

Answer:

Yes. When wastewater systems are overwhelmed, a pass-through event occurs. If more wastewater goes into the system than the system was designed to handle, the system is not going to be able to remove all the contaminants. The contaminants are going to go out the door. So, when introducing new processes in manufacturing, always consider ...

Read More

Traditionally, paint stripping was conducted with methylene chloride or DCM, which is an excellent solvent that was prevalent across many industrial applications. As manufacturers began to learn more about the chemical’s toxicity and carcinogenicity, it quickly ran out of favor as safer alternative methods emerged. Organic paint strippers today are much safer and user-friendly. These products ha...

Read More

Bench testing is not an exact science. Each test can produce slightly different results because every wastewater sample is slightly different. By using bench tests to help determine the best chemicals for the wastewater system, you can eliminate weeks of trial and error on a large scale. You will still need to adjust the wastewater system while the water flows to dial in chemical feeds, but bench ...

Read More

Number 1: Before you put the bath in, passivate the tank and all the plumbing. Passivation is when you’re dissolving the nickel with a nitric acid, using a stainless tank in which you’re putting a passive film which stops it from plating out. A good nitric will stop it from plating out immediately. I’ve seen it happen many times. I’ll get the call and say, “Hey, I put...

Read More

What does Earth Day mean to you? For the metal finishing industry, it means that we continue to make the many parts that make the world go round, from airplane and automobiles to medical devices. If it is metal, we touch it. A side aspect of our industry is that we use millions of gallons of water a year to make these parts. This is water we pull from our communities. In the United States it is es...

Read More

In a recent conversation with Barbara & Ed Kanegsberg (The Cleaning Lady and The Rocket Scientist), we discussed the United States Environmental Protection Agency’s (EPA) Toxic Substance Control Act (TSCA). Congress has asked the EPA to look at existing chemicals and evaluate their risk. They look at them chemical by chemical, step by step.

The risk evaluation is to determine if there ...

Read More

Myth 1 of 8: Water is Obviously “Cheaper” than Solvents.

Regular city water alone won’t clean anything. It needs surfactants and detergents that lower surface tension and remove soils. These are consumed during cleaning and need replenishing. Higher temperatures are needed to activate cleaning chemistry, which is important for ensuring good wetting and evaporation after rinsing, but that con...

Read More

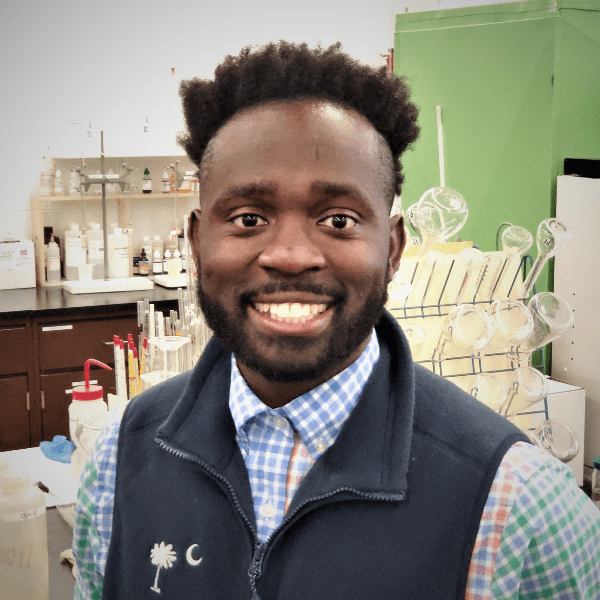

Our Application Specialist, Connor Callais breaks it down for you.

Look at what our Application Specialist, Connor Callais had to say recently showcased in the Hubbard-Hall Seen & Solved podcast.

Connor Callais: Application Specialist Hubbard-Hall

Tim Pennington:

Why would someone choose to use iron phosphates? What are some of the advantages for their process?

Connor Callais:

When you are lo...

Read More

So when we look at manufacturing industries across the board, a lot of people plan for expansion and production, such as adding new lines increasing production hours, and that puts an extra strain on their wastewater systems. We want to future-proof our wastewater systems so that when we do those manufacturing increases, we don’t have to worry later down the line about if our wastewater syst...

Read More

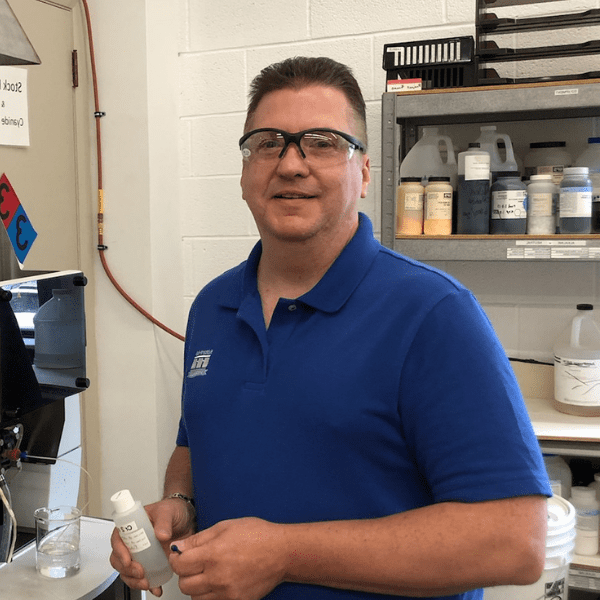

The most common type of corrosion – called atmospheric corrosion – occurs when a metal surface is exposed to oxygen and moisture which then causes a chemical reaction producing iron oxide or rust. For a metal finisher rust is a problem with real consequences. Here we are talking to Larry Ensley, Director of Technical Applications and sharing ideas on how to address it.

Click to Downloa...

Read More

A conversation with Hubbard-Hall’s Joshua McClellan

As a Hubbard-Hall application engineer, Joshua works closely with customers to understand their specific operations and applications of cleaning chemistry to get better results with less chemistry. He has worked with multiple chemical businesses over his career, specializing in chemical application technologies.

Download PDF

What are the p...

Read More

The heart of industry, almost nothing can be manufactured without heat-treating. We recently caught up with Bob Farrell (Senior Vice President and Technical Director at Hubbard-Hall) and asked him a few questions about the heat-treat market, what he has seen in his 30 years of experience and what lies ahead for manufactures using these applications.

Read More: Download the interview PDF

Why are m...

Read More

Black oxide is the conversion of a base metal material to an oxide of that base metal material. A prime example would be Fe3O4, which is black iron oxide, otherwise known as magnetite; another is a CuO, or copper monoxide. It occurs when the chemicals react with a base material to form an oxide of the base’s primary constituent. In the case of stainless steel, not only does it form oxides, but i...

Read More

A conversation with Hubbard Hall’s Jerry Dwyer

Jerry Dwyer CEF, is Hubbard Hall’s market manager for product groups pertaining to heat treating, black oxide and phosphates. His background and experience have established him with knowledgeable insight into the world of heat treating and metal finishing. Dwyer specializes in the above processes and has over a thirty-year history in the heat trea...

Read More

Myths of Cleaning

Myth 1 of 8: Water is Obviously “Cheaper” than Solvents

Regular city water alone won’t clean anything. It needs surfactants and detergents that lower surface tension and remove soils. These are consumed during cleaning and need replenishing. Higher temperatures are needed to activate cleaning chemistry, which is important for ensuring good wetting and evaporation after ...

Read More

Myths of Cleaning

Myth 2 of 8: Aqueous Systems Can’t Be Used in Critical Cleaning

First, let’s be clear that “critical cleaning” has a very specific meaning. It refers to the removal of sub-micron particles and non-volatile residues. It’s required when any surface contamination would yield adverse effects. While many processes and products might qualify, the term is used particul...

Read More

Myths of Cleaning

Myth 3 of 8: Aqueous cleaning is always “safer” than solvent

There’s a misapprehension that “Aqueous Cleaning” refers to cleaning with water. While water is involved, and under the right circumstances can be a solvent, in aqueous cleaning systems the water contains additives. These have several functions, such as lowering surface tension, creating chelation, (the dr...

Read More

Myths of Cleaning

Myth 4 of 8: Solvents are all BAD!

“Solvent” is an extremely broad term. Any substance that will dissolve another is, technically, a solvent, and that includes water. However, in popular parlance, “solvent” often refers to chemicals that will dissolve oil and grease. Examples include acetone, isopropanol, ethanol and butyl acetate. If these names appear familiar it’s be...

Read More

Myths of Cleaning

Myth 5 of 8: Solvents will all be banned through government regulation

It’s true that for some classes of solvents their use either has been or is in the process of being phased out. However, many others are still permitted, although in some cases there are regulations regarding aspects of usage like ventilation. In general, authorities like the EPA take the view that solve...

Read More

Myths of Cleaning

Myth 6 of 8: Solvent cleaning is always the most efficient process

Solvents make very effective cleaners, in the right application. The key points to consider are, what is being cleaned, what is it being cleaned of, and what is it being cleaned for? Solvents are highly effective for dissolving oils and their low surface tension enables good penetration and evaporation. Solvent cl...

Read More

Myths of Cleaning

Myth 7 of 8: Market is Dominated by Aqueous Cleaning

Compared to solvent cleaning, aqueous is still the newcomer, even though it has been in use for two decades. Use of aqueous cleaning is undoubtedly on the rise, but to say it dominates the market is just incorrect. Precision cleaning in particular, is a sector where solvent cleaning dominates.

The key, when choosing a cleaning ...

Read More

Myths of Cleaning

Myth 8 of 8: Cleaning is All About Picking a Chemistry

Chemistry is important for sure. The solvent or aqueous cleaner must be compatible with the soil or contamination you want to remove, but it’s more complicated than that. Consider also the material to be cleaned: some cleaners will damage some surfaces. Then there’s the degree of cleaning or cleanliness desired. O...

Read More